3D Printing Construction Market Size to Worth USD 1,389.08 Billion by 2035

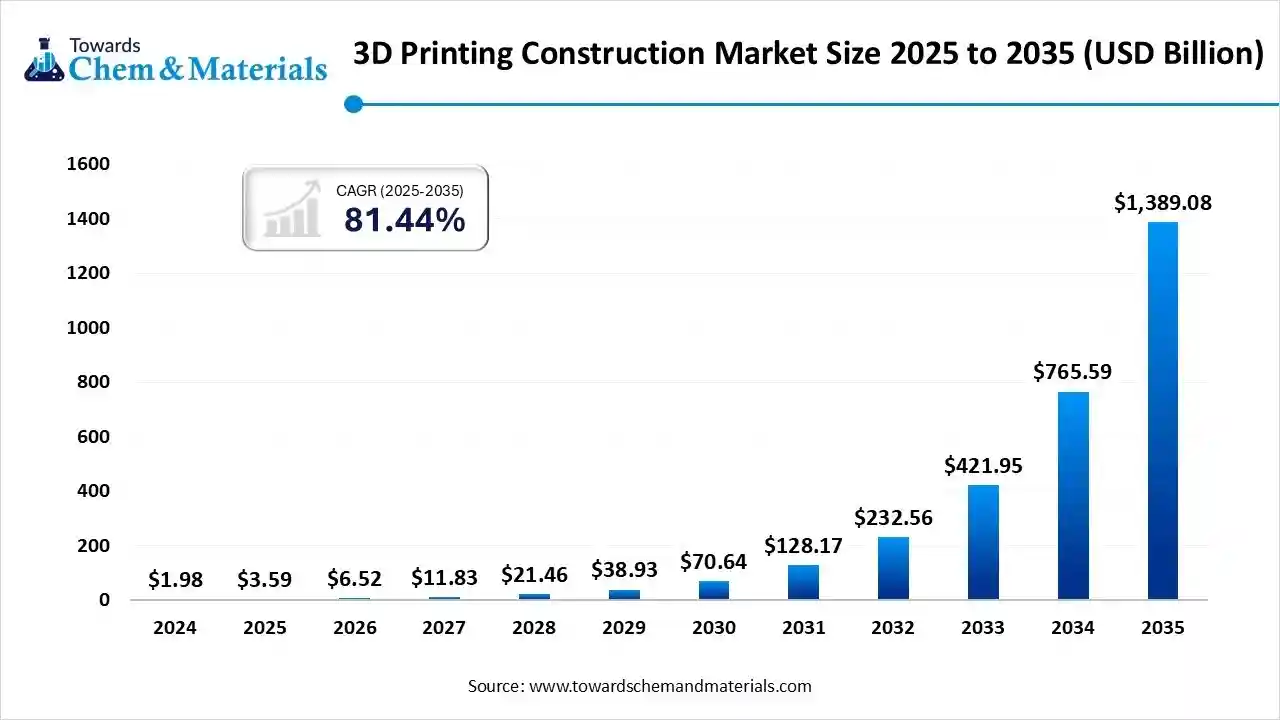

According to Towards Chemical and Materials Consulting, the global 3D printing construction market is projected to grow from USD 3.59 billion in 2025 to USD 1,389.08 billion by 2035, growing at a CAGR of 81.44% from 2025 to 2035.

Ottawa, Nov. 19, 2025 (GLOBE NEWSWIRE) -- The global 3D printing construction market size is calculated at USD 3.59 billion in 2025 and is predicted to increase from USD 6.52 billion in 2026 is expected to be worth around USD 1,389.08 billion by 2035, growing at a compound annual growth rate (CAGR) of 81.44 % over the forecast period 2025 to 2035. The North America 3D printing construction market held the largest share of 46.50% of the global market in 2024. A study published by Towards Chemical and Materials a sister firm of Precedence Research.

The Complete Study is Now Available for Immediate Access | Download the Sample Pages of this Report@ https://www.towardschemandmaterials.com/download-sample/6005

What is 3D Printing Construction?

The 3D printing construction market is transforming the building industry by using additive manufacturing techniques to fabricate structural elements from walls to entire modules via layer-by-layer deposition of materials such as concrete, composites, and polymers. This approach offers rapid, customizable, and more sustainable construction compared to conventional methods, significantly cutting down on labour, material waste, and build times. Adoption is a string of residential, commercial, and infrastructure projects, enabled by large-format printers, on-site robotic systems, and prefabricated modules.

Request Research Report Built Around Your Goals: sales@towardschemandmaterials.com

3D Printing Construction Market Report Highlights

- By region, Asia Pacific dominated the market with a share of 46.5% in 2024.

- By region, Europe is expected to have significant growth in the market in the forecast period.

- By method/technology, the extrusion-based segment dominated the market with a share of 56.8% in 2024.

- By method/technology, the powder bonding segment is expected to grow significantly in the 3D printing construction market during the forecast period.

- By material type, the concrete segment dominated the market with a share of 56.4% in 2024.

- By material type, the composite segment is expected to grow in the forecast period.

- By application/end-use, the building segment dominated the market with a share of 75.5% in 2024.

- By application/end-use, the infrastructure segment is expected to grow in the forecast period.

- By construction form, the on-site segment dominated the 3D printing construction sector with a share of 72.3% in 2024.

- By construction form, the off-site/ prefabrication segment is expected to grow in the forecast period.

Exploring 3D Printing in Construction: A Game-Changer for the Industry

3D printing in construction is transforming the way we build. This cutting-edge technology uses specialized printers to extrude mortar or concrete layer by layer, turning digital designs into actual structures—either incorporating or bypassing traditional methods like casting columns and beams or constructing walls. The result? A dramatic reduction in construction time and a more efficient building process.

What makes 3D printing in construction so remarkable is its precision. Automated systems ensure that every structural element and architectural form is created with incredible accuracy. Whether it’s a simple residential building, a complex commercial project, or architectural design elements, 3D printing offers a level of control that traditional methods can’t match.

Two main materials commonly used in 3D printing construction are 3D Printing Concrete and 3D Printing Mortar. Each has its unique advantages, suited to different needs. This innovation is setting the stage for faster and more sustainable construction in the future.

Read more News Material Informatics Market Size to Cross USD 1,903.75 Mn by 2034

What Are the Major Trends in the 3D Printing Construction Market?

- Growing emphasis on sustainability, with the adoption of low-carbon, bio-based, and recycled materials to reduce environmental impact.

- Increasing autorotation using AI and advanced technology to improve the precision, speed, and scalability of on-site printing.

- Shift toward modular and prefabricated construction, with more off-site 3D printed components being assembled at scale.

- Integration of digital twin and smart monitoring technologies to optimize the real-time performance and lifecycle of 3D printed structures.

Immediate Delivery Available | Buy This Premium Research Report@ https://www.towardschemandmaterials.com/checkout/6005

3D Printing Construction Market Report Scope

| Report Attribute | Details |

| Market Size Value in 2026 | USD 6.52 Billion |

| Revenue Forecast in 2035 | USD 1,389.08 Billion |

| Growth rate | CAGR of 81.44% from 2025 to 2035 |

| Actual data | 2017 - 2025 |

| Forecast Period | 2025 - 2035 |

| Segments Covered | By Method / Technology, By Material Type, By Application / End-Use , By Construction Form, region |

| Regional Scope | North America; Europe; Asia Pacific; Latin America; MEA |

| Country Scope | U.S.; Canada; Mexico; UK; Germany; France; China; Japan; India; South Korea; Australia; Brazil; Kingdom of Saudi Arabia (KSA); UAE; South Africa |

| Key Companies Profiled | COBOD International A/S; Yingchuang Building Technique (Shanghai) Co.Ltd.(Winsun); XtreeE, Apis Cor; WASP S.r.I; CyBe Construction; Sika AG; MX3D; Contour Crafting Corporation; ICON Technology, Inc.; Constructions -3D |

For more information, visit the Towards Chemical and Materials website or email the team at sales@towardschemandmaterials.com| +1 804 441 9344

Benefits of 3D printing in construction Market

3D printing brings great benefits to the construction industry, being a solution that touches almost all areas of the value chain of the sector. From contributions to sustainability, increased productivity and support in challenges on the supply chain, this technology came to revolutionize the way we build.

Time reduction

With traditional construction methods, a project can take many months to complete, with the norm being that large projects take 20% longer than expected and adding up to 80% in cost overruns over the initial budget. However, 3D printing allows to reduce up to 70% of the time and a project can be completed in just hours or days, depending on its magnitude. Therefore, contractors can work on more projects and, consequently, increase their source of income.

More cost-effective and sustainable

3D printing allows the precise amount of material to be used to lift a structure, allowing up to 60% less waste to be generated at the jobsite. Likewise, there will be no surplus in the purchase of materials, assuming a reduction in costs both in its purchase and subsequent storage.

By reducing time and costs, companies will see an exponential increase in the benefits of this technology, which is also of great help in locations where there is a need for projects and a shortage of labor. By automating the creation of a structure through 3D printers, companies can see a reduction in labor costs of up to 80%.

Safer

The U.S. Occupational Safety and Health Administration (OSHA) reports that 1 in 10 workers on construction sites is injured each year, with falls and wrongful contact with equipment being the main causes.

One of the most important benefits that 3D printing has brought to construction is in the health and safety of the employees onsite. By knowing how to work effectively with printers, workers can do their jobs more easily and reduce injuries in the field.

Design flexibility

Last-minute changes to the design will no longer be a problem nor delay the construction process. 3D printing allows you to customize the work until just before starting the printing of the structure, eliminating all the headaches that these changes entail.

How Does AI Influence the Growth of the 3D Printing Construction Industry in 2025?

AI is playing a pivotal role in accelerating the growth of the 3D printing construction industry by enabling smarter, more efficient design and production processes. Through generative algorithms, AI can optimize structural geometry to use less material while maintaining or even improving strength, which makes the printing process more resource-efficient.

AI-powered predictive maintenance monitors printers in real time, forecasting failures before they happen, thereby reducing downtime and increasing uptime for large-scale construction operations. Moreover, AI-driven quality control analyses sensor data during printing to detect defects early, improving the reliability of 3D printed building components.

The Difference Between 3D Printing Concrete Material and 3D Printing Mortar Material for Construction Projects

When it comes to 3D printing in construction, both 3D Concrete and 3D Mortar offer distinct advantages. They differ in surface texture: 3D Concrete has a rougher texture, while 3D Mortar provides a smoother, finer finish. If your project requires a smooth, aesthetically refined surface—such as intricate details for interior or exterior finishes—3D Mortar printing is the ideal choice. It allows for highly detailed printing, resulting in smooth and visually appealing surfaces.

At SCG, we have over 10 years of research, development, and production experience in 3D Mortar formulations. Our patented SCG 3D Mortar is engineered for superior strength and smooth texture. Our expert team provides comprehensive consulting services, ensuring that clients can confidently and accurately integrate 3D printing into their projects.

Market Opportunity

Can 3D Printing Help Solve the Housing Shortage?

3D printing construction offers a major opportunity to support affordable housing as automated building reduces labour needs and speeds up construction. Real projects, such as Habitat for Humanity’s 3D printed homes, show how the technology can be scaled for low-cost neighbourhoods. This creates space for builders and non-profits to expand accessible housing solutions. With the growing demand for rapid, budget, and non-profit organizations to expand accessible housing solutions. With growing demand for rapid, budget-friendly homes, 3D printing stands out as a practical option.

Could Eco-Friendly Materials Drive New Demand?

Sustainable 3D printing materials present an opportunity for companies aiming to reduce emissions in construction. New low-carbon concrete mixes and energy-efficient 3D printed structures attract customers focused on greener building practices. This gives developers a chance to differentiate through environmental benefits. As climate goals intensify, green 3D-printing solutions may gain strong traction.

Immediate Delivery Available | Buy This Premium Research Report@ https://www.towardschemandmaterials.com/checkout/6005

3D Printing Construction Market Segmentation Insights

Method/ Technology Insights:

Why has the Extrusion-Based Segment Dominated the 3D Printing Construction Market?

The extrusion-based segment held a dominant position in the market in 2024. This segment dominates the market because extrusion technology allows continuous, large-scale deposition, enabling builders to create entire walls and structural components with high efficiency and material flexibility. Its simplicity, reliability, and compatibility with construction-grade concrete make it the preferred choice for companies seeking faster and automated building processes. The method supports both on-site and off-site printing, giving construction firms the freedom to adapt to different project requirements.

The powder bonding segment is expected to grow at the fastest rate between 2024 and 2034. Powder-boding is emerging as the fastest-growing technology because it enables highly detailed, complex architectural structures that traditional building methods cannot easily achieve. This method supports a wider range of advanced materials, encouraging innovation in lightweight construction, decorative elements, and efficient structural design.

Material Type Insights:

How Concrete Segment Held the Largest Share of the 3D printing construction Market in 2024?

The concretes segment maintained a leading position in the market in 2024. Concrete dominates the market because it provides a strong, durable, and cost-efficient material suitable for a wide range of residential, commercial, and infrastructure projects. Construction-grade concrete mixtures used in 3D printing allow smooth extrusion, rapid setting, and enhanced structural stability, making them ideal for building load-bearing components.

The material’s widespread availability and compatibility with large-format printers further strengthen its market position. With increasing emphasis on sustainable and resilient buildings, modified low-carbon concrete blends are also gaining traction. As the technology expands globally, concrete remains the backbone of most 3D-printed construction applications.

The composite segment is projected to expand rapidly in the market during the forecast period. Composites are becoming the fastest-growing material option because they offer superior strength-to-weight ratios, design flexibility, and enhanced durability compared to traditional construction materials. Their adaptability makes them suitable for specialized components, modular structures, and eco-friendly building solutions.

Composites also support the use of recycled or bio-based inputs, aligning with the industry’s push toward greener construction. Their performance benefits allow architects to create complex or lightweight structures while maintaining safety and durability. This mix of innovation potential and sustainability is driving broader adoption of composite materials in future 3D-printed construction projects.

Application/End-use Insights:

Which Application Segment Dominated the 3D printing construction Market in 2024?

The building segment dominated the market in 2024. The building segment dominates because 3D printing is increasingly used to construct homes, commercial spaces, and low-rise structures with lower labor requirements and faster project timelines. Its ability to automate large portions of the building process reduces human error and material waste, making it attractive for developers.

The technology also allows for high customization, enabling unique architectural designs and improved space utilization. Growing demand for affordable housing and sustainable communities further strengthens its market position. As cities expand and housing shortages intensify, 3D-printed buildings continue to gain priority among governments and construction companies.

The infrastructure segment is predicted to witness high growth over the forecast period. Infrastructure is emerging as the fastest-growing segment because 3D printing offers efficient solutions for producing bridges, walkways, barriers, and urban fixtures with reduced costs and shorter construction cycles. The technology supports stronger and more durable geometries, helping solve long-standing infrastructure challenges.

Governments are exploring 3D printing to accelerate public works while minimizing material waste and environmental impact. Automated production allows quick deployment in remote or emergency areas where conventional construction is slow or expensive. As the modernization of public infrastructure becomes a global priority, this segment is poised for rapid expansion.

Construction Form Insights:

What made the On-Site Segment Dominate the 3D printing construction Market?

The on-site segment captured a significant portion of the market in 2024. On-site construction dominates because it allows entire structures to be printed directly at the building location, eliminating the need to transport large components. This reduces logistics costs and enables builders to work efficiently on uneven or complex terrain.

On-site printing also supports rapid deployment for housing projects, disaster relief shelters, and remote-area construction. The method enhances flexibility, allowing real-time modifications during printing. As the construction industry seeks faster and more adaptive building methods, on-site 3D printing continues to be widely adopted.

The off-site/prefabrication segment is set to experience the fastest rate of market growth from 2025 to 2035. Off-site prefabrication is the fastest-growing construction form because it ensures controlled manufacturing conditions, higher precision, and better quality consistency for printed components. Printing structures in factories reduces environmental impact and minimizes weather-related delays.

Prefabrication allows mass production of standardized modules that can be transported and assembled quickly, making it ideal for large housing projects and commercial developments. This method also improves safety by reducing on-site labor requirements. As modular construction becomes more popular worldwide, off-site 3D printing is rapidly becoming a preferred approach for scalable, industrialized building production.

Regional Insights

Why Is Asia Pacific Dominating The 3D-Printing Construction Market?

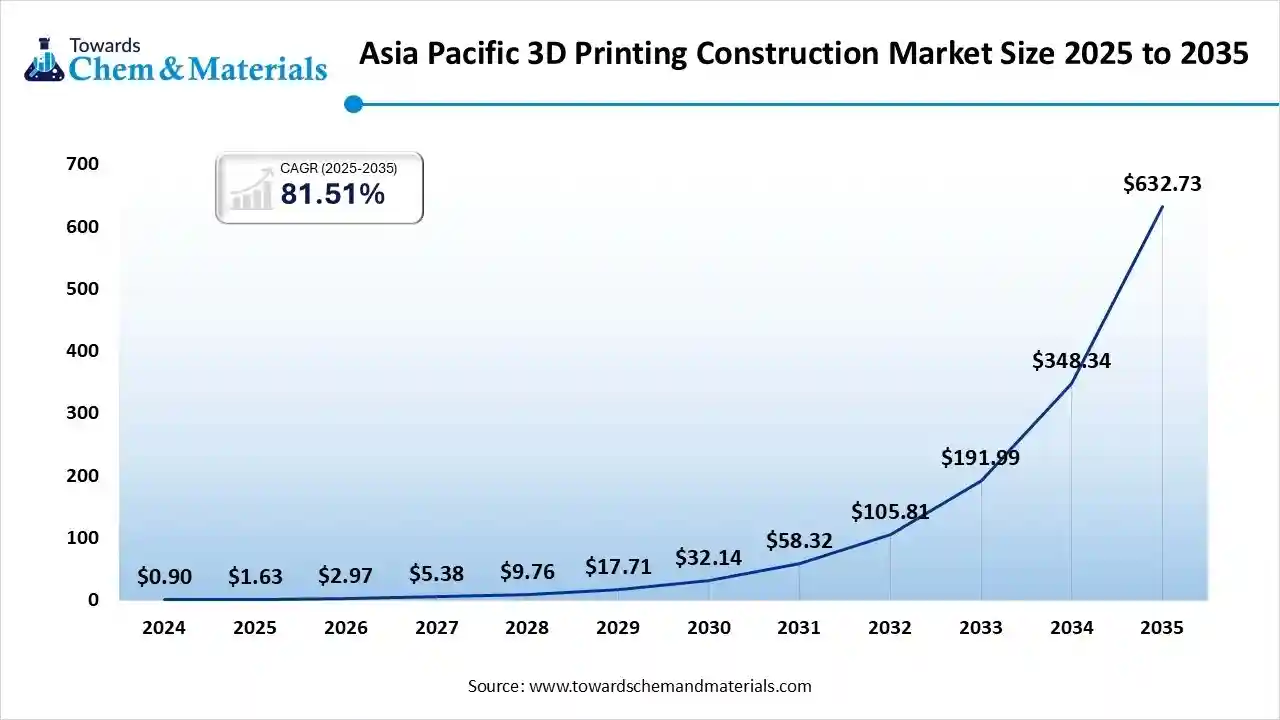

The Asia Pacific 3D printing construction market size was valued at USD 1.63 billion in 2025 and is expected to surpass around USD 632.73 billion by 2035, expanding at a compound annual growth rate (CAGR) of 81.51% over the forecast period from 2025 to 2035. Asia Pacific dominated the market, accounting for 46.5% in 2024.

The Asia Pacific region is dominating the market in 2024, driven by rapid urbanization, large-scale infrastructure development, and favourable government policies promoting construction automation. Key economies like China, India, and Japan are aggressively adopting 3D-printing technology to meet housing demand and modernize urban growth. The region’s strong manufacturing base and lower material costs further boost its competitiveness. Moreover, public-private investment in pilot projects like 3D-printed homes and bridges is accelerating real-world development.

India 3D-Printing Construction Market Trends

India is rapidly becoming a key player in the 3D-printing construction space, fuelled by smart city initiatives, affordable housing needs, and government backing for innovation. Local partnerships between construction firms and technology start-ups are enabling 3D-printed residential and disaster-resistant structures. The growing use of sustainable materials such as recycled concrete and geopolymer cement aligns with national goals for eco-friendly construction.

North America 3D-Printing Construction Market Trends

The 3D printing construction market in North America is expected to register a considerable growth rate from 2025 to 2035. The private sector's growing interest in adopting 3D printing technology for construction is a crucial driver of the market in North America. Construction companies, architects, and developers increasingly recognize the potential benefits of integrating 3D printing into their workflows. By experimenting with new design methodologies and leveraging the flexibility of 3D printing, industry players can differentiate themselves in a competitive market.

In addition, the emergence of specialized firms focused on 3D printed construction solutions further accelerates market growth, as these companies provide expertise and tailored offerings to meet diverse client needs. For instance, in December 2023, Mighty Buildings, a 3D printing for construction company, announced a USD 5 million grant to create sustainable and affordable housing in the San Francisco Bay Area. The grant will support developing, testing, and demonstrating cost-effective modular homes that are zero- or near-zero-carbon and can be quickly deployed. The project includes the construction of three prefabricated low-carbon townhouses in Bay Point, California.

U.S. 3D Printing Construction Market Trends

The demand for 3D printing construction in the U.S. is experiencing significant growth. The U.S. government is increasingly recognizing the potential of 3D printing in construction and is providing support through various initiatives and funding programs. Federal and state-level investments in research and development are fostering innovation within the industry, encouraging partnerships between the public and private sectors to explore advanced construction technologies.

In addition, government incentives aimed at promoting affordable housing and sustainable building practices can stimulate interest in 3D-printed construction solutions. This supportive environment is vital for accelerating the adoption of these technologies. In April 2022, The Defense Department (DOD), collaborating with the private sector, is constructing three transient training barracks utilizing cutting-edge 3D printing technology. Led by the Defense Innovation Unit, this project will be finished within 10 months. Each barrack will span over 5,700 square feet, making them the largest 3D-printed buildings in the Americas. Additionally, these barracks will be the first structures created using 3D printing to adhere to the DOD's established Unified Facilities Criteria for additive concrete construction, which provides guidelines for DOD projects.

Why Is Europe the Growing Region in 3D Printing Construction?

Europe is set to experience the fastest growth in the market, driven by its strong focus on sustainability, precision, and advanced manufacturing. Countries such as the Netherlands, Germany, and Denmark are pioneering large-scale 3D printed buildings and infrastructure, making the region a hotbed for innovation and adoption. High regulatory standards around energy efficiency and carbon emissions are pushing construction firms toward additive manufacturing to reduce waste and lower environmental impact.

The UK 3D-Printing Construction Market Trends

The UK is emerging as a dominant player in Europe’s market, underpinned by strong government investments in modernizing infrastructure, which are driving net-zero building goals. UK universities and tech firms are pushing the boundaries of large-format additive construction, enabling on-site and modular 3D prints. High public and private demand for sustainable, cost-efficient housing and infrastructure aligns well with the capabilities of 3D printing technology.

Top Companies 3D Printing Construction Market & Their Offerings:

- COBOD International A/S: A global leader that supplies 3D printers for construction projects on six continents, with shareholders including General Electric, CEMEX, and Holcim.

- ICON Technology, Inc.: An American company that provides 3D-printed homes for residential, affordable housing, and defense projects, using proprietary materials like Lavacrete and CarbonX.

- Yingchuang Building Technique (WinSun): A Chinese company that gained attention for 3D printing multiple houses in 24 hours using recycled materials and has since developed multi-story buildings.

- Apis Cor: A company known for its robotic arm-based 3D printing technology.

- Mighty Buildings: A company focused on 3D printing residential homes, particularly for the real estate sector.

- CyBe Construction: A Dutch company that develops 3D printers, materials, and software for construction.

-

XtreeE: A French company providing large-scale 3D printing technology for architectural and construction projects.

More Insights in Towards Chemical and Materials:

- Material Informatics Market Size | Companies Analysis 2025- 2034

- U.S. Construction Chemicals Market Size | Companies Analysis 2025-2034

- Low-Carbon Construction Material Market Size to Hit USD 601.63 Bn by 2034

- Building & Construction Materials Market Size to Reach USD 3.90 Trillion by 2034

- Construction Chemicals Market Size to Reach USD 72.7 Billion by 2034

- Sustainable Construction Material Market Prices, News, Monitor, Market Analysis & Demand

3D Printing Construction Market Top Key Companies:

- Apis Cor

- COBOD International A/S

- Constructions -3D

- Contour Crafting Corporation

- CyBe Construction

- ICON Technology, Inc.

- MX3D

- Sika AG

- WASP S.r.I

- XtreeE

- Yingchuang Building Technique (Shanghai) Co.Ltd.(Winsun)

Recent Developments

- In March 2024, ICON Technology, Inc., specializing in advanced construction technologies and large-scale 3D printing, launched a new suite of products and innovations to automate the construction process further. This includes a groundbreaking robotic printer that facilitates multi-story construction, a digital catalog, a low-carbon building material featuring over sixty ready-to-build home designs, and an AI Architect to assist with home design and construction. ICON asserts that these integrated technologies create a more efficient and sustainable construction platform, enabling the affordable delivery of high-quality housing globally.

- In July 2025, in bold move, icon is constructing a dozen 3D printed homes in Austin’s Muller neighbourhood, including three units under the city’s affordable housing program. These homes use Icon’s Vulcan printer to build the lower floors, promising faster construction, high insulation, and lower labor needs.

- In October 2025, India has unveiled its first 3D printed rural house in Roorkee, built under the PMAY-G scheme. Developed with eco-friendly concrete technology, this prototype aims to bring scalable, low-cost, and sustainable housing to underserved rural areas.

3D Printing Construction Market Report Segmentation

This report forecasts revenue growth at global, regional, and country levels and provides an analysis of the latest industry trends in each of the sub-segments from 2019 to 2035. For this study, Towards Chemical and Materials has segmented the global 3D Printing Construction Market

By Method / Technology

- Extrusion-based

- Powder Bonding

- Others (Wire-Arc Additive, Robotic Arm, etc.)

By Material Type

- Concrete

- Metal

- Composite

- Others (Polymers, Geopolymers)

By Application / End-Use

- Building (Residential, Commercial, Industrial)

- Infrastructure (Bridges, Tunnels, Utility components)

By Construction Form

- On-site (printing at location)

Off-site / Prefabrication (modules printed off-site then assembled)

By Regional

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East & Africa

Immediate Delivery Available | Buy This Premium Research Report@ https://www.towardschemandmaterials.com/checkout/6005

About Us

Towards Chemical and Materials is a leading global consulting firm specializing in providing comprehensive and strategic research solutions across the chemical and materials industries. With a highly skilled and experienced consultant team, we offer a wide range of services designed to empower businesses with valuable insights and actionable recommendations.

Our Trusted Data Partners

Towards chem and Material | Precedence Research | Statifacts | Towards Packaging | Towards Healthcare | Towards Food and Beverages | Towards Automotive | Towards Consumer Goods | Nova One Advisor | Nutraceuticals Func Foods | Onco Quant | Sustainability Quant | Specialty Chemicals Analytics

For Latest Update Follow Us: https://www.linkedin.com/company/towards-chem-and-materials/

USA: +1 804 441 9344

APAC: +61 485 981 310 or +91 87933 22019

Europe: +44 7383 092 044

Email: sales@towardschemandmaterials.com

Web: https://www.towardschemandmaterials.com/

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.